RESINDEK® FOR AGV & AMR WAREHOUSE ROBOTS

MOBILE ROBOT FLOORING FOR AGV AND AMR TRAFFIC

Flooring for Mobile Robots

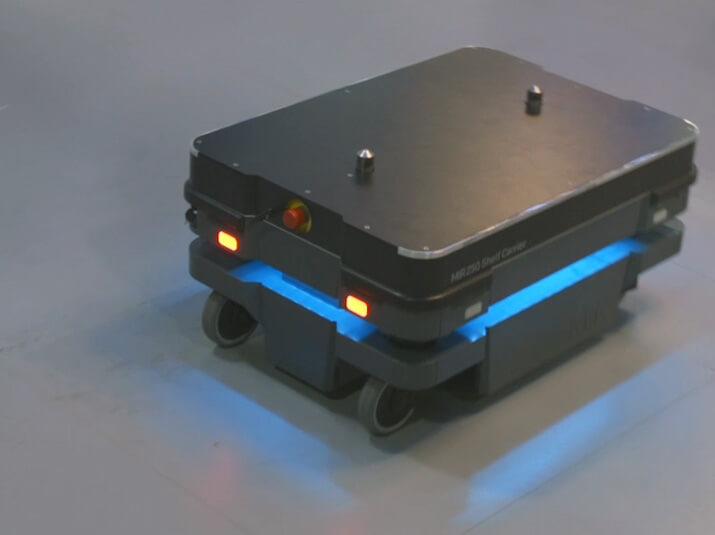

Choosing the right flooring is critical for optimizing the performance and efficiency of mobile robots in your facility. ResinDek® panels by Cornerstone Specialty Wood Products are engineered specifically to meet the demanding requirements of Autonomous Mobile Robots (AMRs) and Automated Guided Vehicles (AGVs), ensuring seamless operation and long-term durability.

As the manufacturer of ResinDek® panels, we have been at the forefront of testing and innovating flooring panels for the Material Handling Industry since 1994. In 2007, we began providing ResinDek panels for automated warehouse distribution robots. Much of our initial research and development occurred with Automated Guided Vehicles. In the last decade, we have provided a variety of ResinDek engineered flooring products to numerous Automated Guided Vehicles (AGV) and Autonomous Mobile Robot (AMR) manufacturers for their testing labs. As a result, millions of square feet of ResinDek panels are in service worldwide with robotic traffic in distribution centers, warehouses, microfulfillment centers, and retail environments.

At Cornerstone Specialty Wood Products, we understand that the AMR flooring solutions and AGV flooring solutions can be complex, and there may be a variety of demands within a single project. Automated warehouse robots need to move quickly and operate as efficiently as possible, and we recognize that the floor finish plays a crucial role in how well the robots perform. Coefficient friction, surface roughness, floor flatness, gloss, and wear can all affect the ability of robots to run at their peak. We offer a multitude of ResinDek flooring options that can be customized for load capacities, required finish type, and volume of robotic traffic. The optimization of all these criteria provides an extremely cost-effective robotic flooring solution that is tailored for each project. ResinDek panels are custom manufactured with engineered processes which enhance the functionality, durability, and life of the floor. ResinDek finishes are developed by our internal coating innovation lab where innovation never stops. Premium materials and unsurpassed manufacturing methods ensure that every ResinDek floor panel will withstand the rigorous requirements of autonomous mobile robots and automated guided vehicles.

RESINDEK® FLOORING FINISHES FOR AUTOMATED WAREHOUSE ROBOTS

The durability and condition of the floor are important considerations for the optimal performance of AGVs and AMRs. Worn, uneven surfaces can disrupt the functioning of the vehicle's laser-based navigation sensors, slowing down its rate of travel. Coefficient of friction can impact the robot's acceleration, stopping accuracy, and turning. Gloss and light reflectivity can affect the fluidity and accuracy of the robot. To meet these demands of various robots, ResinDek panels are available in three unique finishes for automated warehouse robots: TriGard® ESD, TriGard® ESD Ultra and MetaGard® SST. TriGard® ESD and TriGard® ESD Ultra utilize our unique coating technology that is engineered and designed specifically for robotic traffic: TriGard® ESD Coating is the perfect flooring finish for autonomous mobile robots that use lidar navigation system or a variable path. TriGard® ESD Ultra is a new, innovative finish that provides more than 4X greater wear than the TriGard® ESD coating. TriGard® ESD Ultra is engineered for ultra-high repetitive travel patterns and defined travel paths. When required, the TriGard® ESD Ultra coating can be modified for increased surface roughness or a higher or lower reflectivity. ResinDek with MetaGard® SST is designed to withstand millions of repetitive cycles typically found with AGVs in areas where dirt or debris accumulate 24/7 and is not routinely cleaned. ResinDek with MetaGard® SST features a steel surface that encapsulates the ResinDek flooring panel.

| Description | Reference Standard | Test Procedure | TriGard® ESD | TriGard® ESD Ultra | MetaGard® SST |

|---|---|---|---|---|---|

| Coefficient of Friction: BOT 3000E |

ASTM A326.3 | Neolite sensor has material that is 95+/-3 Shore A | Avg Dry: 0.62 Avg Wet: 0.28 |

Avg Dry: 0.62 Avg Wet: 0.47 |

Avg Dry: 0.77 Avg Wet: 0.68 |

| Abrasion Class | |||||

| ASTM D4060 | 180 grit aluminum oxide sandpaper replaced every 500 cycles with 1kg of weight | Wear Revolutions: 6,000 | Wear Revolutions: 24,000 | Wear Revolutions: >50,000 | |

| EN 13329 | European surface evaluation using sandpaper wheels | AC6 | AC6 | ||

| Gloss, 85 deg | ASTM D523 | Tested with glossmeter geometries of 85° | 7 GRUs | 7 GRUs | 8 GRUs |

Need help deciding which robotic flooring solution is right for you?

CONTACT USRESINDEK® FLOORING PANELS FOR WAREHOUSE MOBILE ROBOTS

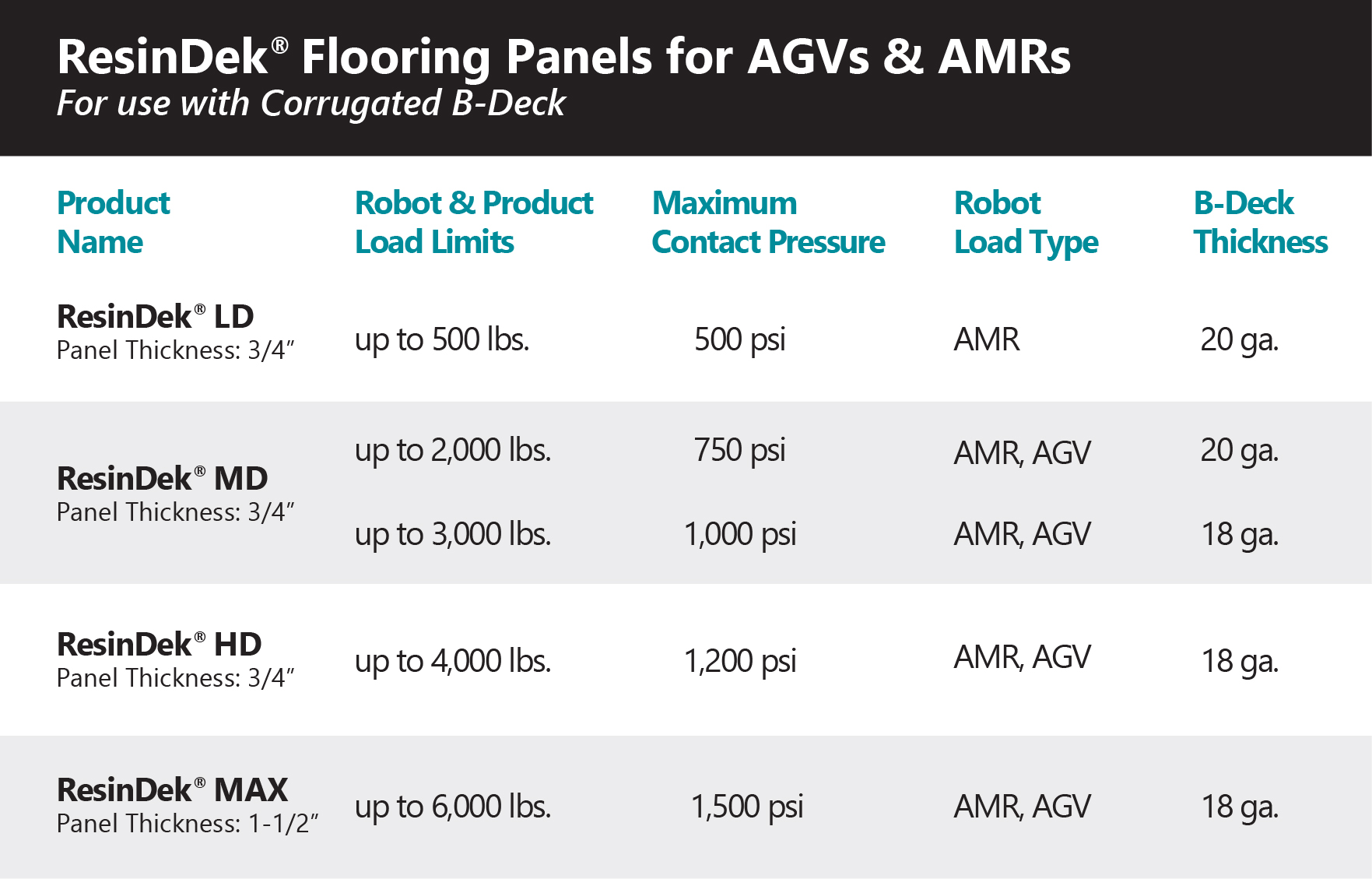

RESINDEK FLOORING PANELS - For Use with Corrugated B-Deck

ResinDek® LD

3/4" Thick Panel

Robot loads up to 500 lbs.

Pallet loads up to 2,000 lbs.

ResinDek® MD

3/4" Thick Panel

Robot loads up to 2,000 lbs.

Pallet loads up to 3,500 lbs.

ResinDek® HD

3/4" Thick Panel

Robot loads up to 4,000 lbs.

Pallet loads up to 4,500 lbs.

ResinDek® WR

3/4" Thick Panel

Robot loads up to 500 lbs.

Pallet loads up to 2,000 lbs.

ResinDek® MAX

1-1/2" Thick Panel

Robot loads up to 6,000 lbs.

Pallet loads up to 8,000 lbs.

* Loads above include both weight of robot + product.

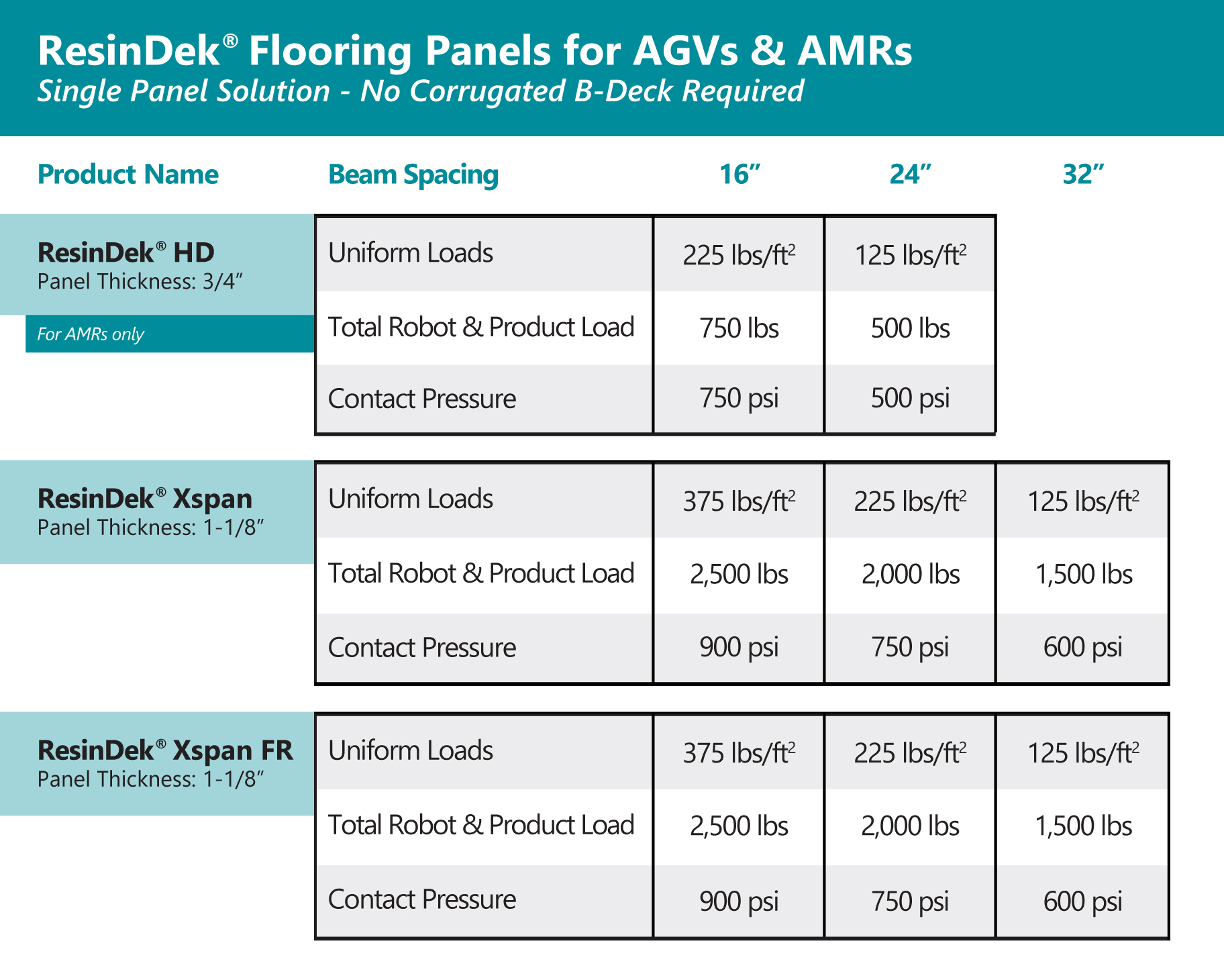

RESINDEK FLOORING PANELS - Single Panel Solution - No Corrugated B-Deck Required

ResinDek® HD

3/4" Thick Panel

Robot loads up to 750 lbs.

ResinDek® Xspan®

1-1/8" Thick Panel

Robot loads up to 2,500 lbs.

Pallet loads up to 3,000 lbs.

ResinDek® Xspan® FR

1-1/8" Thick Panel

Robot loads up to 2,500 lbs.

Pallet loads up to 3,000 lbs.

* Loads above include both weight of robot + product and are calculated on 16" beam spacing.

RESINDEK FLOORING PANELS – Overlay Solution

ResinDek® ReShield™

1/4" Thick Panel

Robot loads up to 3,000 lbs.

Pallet loads up to 3,500 lbs.

* ResinDek ReShield allowable loads are dependent upon the substrate that it is being installed on.

ResinDek panels are backed by comprehensive engineering services and a 10-year product warranty. The panels are formulated in different thicknesses and densities to meet the requirements of varying load capacities. The engineered composite wood panels have the structural integrity to support dynamic and static rolling loads from 500 to 6,000 lbs while handling the rigorous demands of automated guided vehicles and autonomous mobile robots.

Each ResinDek panel features a tongue-and-groove configuration promoting effective panel to panel wheel load transfer. When required, tongue and groove configurations are available on all 4 sides. ResinDek panels with TriGard® ESD and TriGard® ESD Ultra are available in sizes up to 4' x 10' (1219 mm x 3048 mm). ResinDek with MetaGard maximum size is 4'x 8' (1219 mm x 2438 mm).

HEAVY DUTY FLOORS FOR AGV & AMR ROBOTIC TRAFFIC

| Number of AGV and AMR Passes for Each Finish | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Product Name | Thickness | Robot & Product Load Limits |

Maximum Contact Pressure |

Substructure | TriGard® ESD | TriGard® ESD Ultra | MetaGard® SST | |||

| AMR* | AGV** | AMR* | AGV** | AMR* | AGV** | |||||

| ResinDek® LD | 3/4" / 19mm | 500lbs / 230kgs | 500psi / 3.4MPa | 20GA / 0.9mm B-Deck | ≤ 20M | ≤ 50M | ≤ 100M | |||

| ResinDek® MD | 3/4" / 19mm | 2000lbs / 910kgs | 750psi / 5.2MPa | 20GA / 0.9mm B-Deck | ≤ 20M | ≤ 5M | ≤ 50M | ≤ 20M | ≤ 100M | ≤ 50M |

| 3/4" / 19mm | 3000lbs / 1365kgs | 1000psi / 6.9MPa | 18GA / 1.2mm B-Deck | ≤ 20M | ≤ 5M | ≤ 50M | ≤ 20M | ≤ 100M | ≤ 50M | |

| ResinDek® HD | 3/4" / 19mm | 4000lbs / 1815kgs | 1200psi / 8.3MPa | 18GA / 1.2mm B-Deck | ≤ 20M | ≤ 5M | ≤ 50M | ≤ 20M | ≤ 100M | ≤ 50M |

| 3/4" / 19mm | 750lbs / 345kgs | 750psi / 5.2MPa | Steel beams/purlins | ≤ 20M | ≤ 5M | ≤ 50M | ≤ 20M | ≤ 100M | ≤ 50M | |

| ResinDek® WR | 3/4" / 19mm | 500lbs / 230kgs | 500psi / 3.4MPa | 20GA / 0.9mm B-Deck | ≤ 20M | ≤ 50M | ≤ 100M | |||

| ResinDek® MAX | 1-1/2" / 38mm | 6000lbs / 2725kgs | 1500psi / 10.3MPa | 18GA / 1.2mm B-Deck | ≤ 20M | ≤ 5M | ≤ 50M | ≤ 20M | ≤ 100M | ≤ 50M |

| ResinDek® Xspan® / Xspan® FR | 1-1/8" / 28mm | 2500lbs / 1135kgs | 900psi / 6.2MPa | Steel beams/purlins | ≤ 20M | ≤ 5M | ≤ 50M | ≤ 20M | ≤ 100M | ≤ 50M |

| ResinDek® ReShield™ | 1/4" / 6mm | 3000lbs / 1365kgs | 1000psi / 6.9MPa | See Note Below*** | ≤ 20M | ≤ 5M | ≤ 50M | ≤ 20M | ||

NOTE:

- For flooring used with corrugated b-deck: Please note load values above are calculated on 36" beam spacing, increased spacing will increase deflection and/or decrease capacity.

- For flooring used with steel beams: Please note load values above are calculated on 16" beam spacing, increased spacing will increase deflection and/or decrease capacity.

- The wear life of the topside finish is dependent on the robot loads, wheels, frequency of cleaning and regular maintenance.

- * AMRs are mobile robots that navigate freely without following floor markings. They adapt their routes around obstacles and typically carry lighter loads than AGVs, causing less floor wear.

- ** AGVs are guided robots that follow floor markings. They're heavier and carrier bigger loads than AMRs. AGVs stop when they meet obstacles. Their fixed paths cause more wear on specific floor areas.

- *** ResinDek ReShield allowable loads are dependent upon the substrate that it is being installed on. Contact us for more information.

NOTE:

- Testing was completed with polyurethane caster wheels and any deviation or alternative wheels such as crowned, steel or plastic could void the warranty. Contact CSWP for more information.

- Contact pressure values are to be used as a guide. Please consult factory for specific robot usage.

- For flooring used with corrugated b-deck: Please note load values above are calculated on 36" beam spacing, increased spacing will increase deflection and/or decrease capacity.

- For flooring solutions with no b-deck: All allowable loads are based on a two span condition. Uniform load values are based on L/240 deflections, any deviation can positively or negatively impact these values. Please contact Cornerstone for other span conditions. The calculations and load tables to the left have been compiled based on specified calculation methods and assumptions. The loads provided are for the purpose of information for preliminary studies and cannot be used as a reference in structural studies. Contact an accredited engineering office or architect to perform a complete stability analysis.

FASTENING SYSTEMS FOR ROBOTIC APPLICATIONS

To ensure the level flooring surface critical for the success of robotic navigation, Cornerstone Specialty Wood Products, LLC® offers a complete package of engineered fastening systems. These engineered solutions allow installers to securely fasten ResinDek® panels for robotic applications quickly and easily.

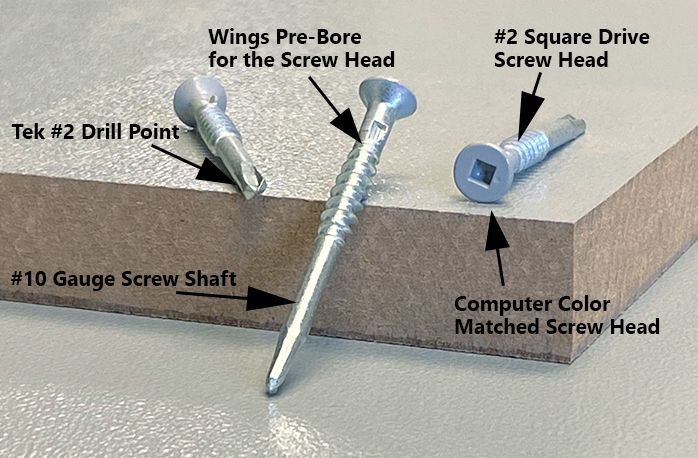

+ TOP SIDE ENGINEERED FASTENERS

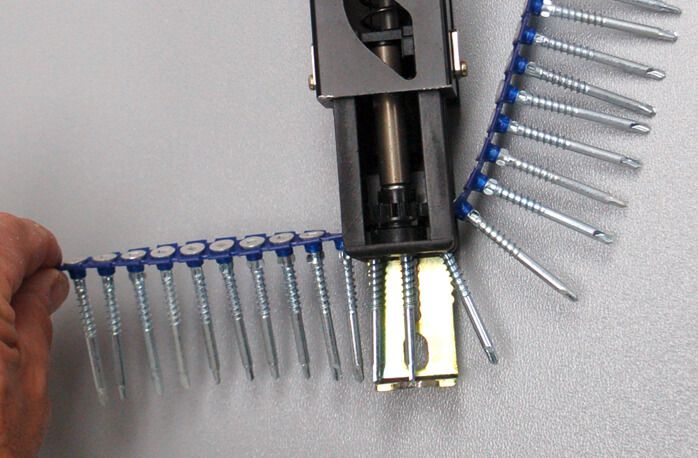

Strong, durable, and easy to install, ResinDek® engineered fasteners secure the flooring panels with no countersinking or pre-drilling necessary. They are designed with wings near the top of the shaft that create a counter-bore for screw heads. The fasteners' number 2 square drive head works with the drill point to effortlessly penetrate steel decking thicknesses up to 12-gauge. To prevent the ResinDek® panels from lifting during installation, the fasteners are designed to drill through both the panel and steel decking before the threads engage.

Features of the top-side engineered fasteners:

- Offered in collated strips for fast feed installation

- Robust #10 wire gauge screw

- Zinc coating is corrosion resistant in high humidity applications

- Fasteners may be specified in gray or beige

- Install easily with Cornerstone's stand-up screwdriver

+ Stand-Up Screwdriver for Engineered Fasteners

Designed specifically for panels that are secured from their top surface, Cornerstone's stand-up screwdriver works with collated strips of ResinDek® engineered fasteners. Together, the system cuts fastening costs by up to 40%, while its ergonomic design significantly reduces fatigue during installation.

Other stand-up screwdriver advantages include:

- Greater control over settings to achieve more consistent screw depth

- Easy setup and assembly

- Collated strips of fasteners are easy to load

- Bit tip replacements are fast and simple to install

- Intuitive operation cuts training time

- Includes case for safe transport and storage when not in use

- Warrantied for 1-year by manufacturer

+ Collated Screws for Corrugated Metal Deck

Designed for applications in which ResinDek® panels are installed over structural metal B-Deck decking, Cornerstone's engineered fasteners work best with roll form beams and structural steel less than 3/16" thick. B-Deck valley widths less than 2-1/2" may not accommodate Cornerstone's stand-up screwdriver. Contact Cornerstone Specialty Wood Products for more guidance and recommendations.

Notes:

- The fastening systems detailed above are intended for ResinDek® LD, MD and HD.

- Other fastening systems are offered. Contact Cornerstone for details.

+ INVISI-LOC® UNDERSIDE ENGINEERED FASTENING SYSTEM

The Invisi-Loc® under deck engineered fastening system is used to secure ResinDek® panels from underneath the mezzanine structure. This eliminates visible fasteners on the flooring surface. Dependable, economical, and easy to use, the fasteners and flooring panels can be installed with Cornerstone's pre-punched corrugated metal decking, which cuts installation time and eliminates metal shavings.

- Each 4' x 8' ResinDek® panel requires 20 Invisi-Loc® engineered fasteners. The fasteners are installed with a pneudraulic installation tool (offered by Cornerstone Specialty Wood Producrts) powered by a standard, medium-duty air compressor.

- Pre-punched corrugated metal decking and structural metal B-Deck fastens to the bar joists with drilling screws or welding (like other steel decking).

- Cornerstone Specialty Wood Products offers all required pneudraulic installation tools for rent or purchase.

- The Invisi-Loc® under deck engineered fastening system is covered by a 10-year warranty when installed per Cornerstone Specialty Wood Products specifications.

MOBILE ROBOT FLOORING RESOURCES

AGV & AMR CASE STUDIES

DOWNLOAD OUR WHITE PAPERS

SEE HOW AUTOMATED WAREHOUSE ROBOTS PERFORM ON RESINDEK FLOORING PANELS

The Flooring Solution for Robotic Traffic | Video Length: 2:03

ResinDek Flooring Panels Inside a Distribution Center | Video Length: 4:09

Elevated Flooring Solutions for AGVs and AMRs | Video Length: 2:54

LITERATURE, SPECIFICATIONS & DATA SHEETS

MOBILE ROBOT FLOORING LITERATURE

RESINDEK FLOORING SPEC SHEETS

DATA SHEETS

CODE COMPLIANCE & CERTIFICATIONS

A number of independent evaluation and certification organizations have assessed ResinDek® engineered flooring panels to verify their suitability in multiple applications. These include IAPMO Uniform Evaluation Services (UES) verification that ResinDek® panels comply with multiple building codes and fire resistance ratings, including those from the International Building Code (IBC), International Residential Code (IRC), and Underwriters Laboratories (UL). Futher, IAPMO confirmed their suitability for use in Types I-V construction and as part of a fire-resistance rated assembly.

As part of Cornerstone Specialty Wood Products, LLC's commitment to environmental sustainability, all ResinDek® panels are certified by SCS Global Services for use of recycled materials and to have no added formaldehyde. They also contribute towards earning points for LEED® qualified buildings. ResinDek® panels may also be specified for construction with FSC® certified materials (FSC® License Code FSC-C124474).

+ Evaluation Service Report, Fire Compliance & UL

EVALUATION SERVICE REPORT & FIRE COMPLIANCE

A Uniform Evaluation Service Report has been issued by IAPMO's Uniform Evaluation Service (UES) verifying that Cornerstone's ResinDek® engineered flooring panels comply with International Building Code (IBC), International Residential Code (IRC) and UL Fire-Resistance Ratings.

ResinDek® panels were further evaluated by the ANSI-accredited, independent, third-party IAPMO organization for their suitability for use in Types I-V construction, and as part of a fire-resistance rated assembly (when properly installed). The rigorous assessment reviewed the panels' physical, structural, surface burning, fire-resistance, and ignition properties.

ResinDek panels are audited annually to provide the most up-to-date information possible to local building officials' review.

Two UES Reports on ResinDek engineered flooring panels are available and shared below: one for the United States, and the second for Canada and its provinces. Contact Cornerstone for more fire code compliance information.

UL Classification

Underwriters Laboratories (UL) certified ResinDek® engineered flooring panels as UL Classified for up to a 2-hour fire rated assembly under UL Design No. L701 and UL File No. R39265.

+ SCS, FSC & LEED

Environmental sustainability has been a fundamental value of Cornerstone Specialty Wood Products, LLC® since the beginning. Because our business relies on the manufacture of highly engineered products, we have specifically created processes that do not negatively affect the environment. As part of that commitment, we annually submit our ResinDek® engineered flooring panels for independent, third-party evaluation and certification of our Earth-friendly processes.

SCS CERTIFIED

As part of Cornerstone's commitment to environmental stewardship — and to confirm our responsible use of the planet's natural resources — our ResinDek® engineered flooring panels are reviewed and validated by SCS Global Services annually. SCS is an international leader in third-party quality, environmental, and sustainability verification, certification, auditing, testing, and standards development.

Cornerstone's SCS Certifications are shared below.

FSC® CERTIFIED

Working to improve forest management around the world, the Forest Stewardship Council® (FSC®) is not-for-profit organization dedicated to promoting the responsible use of this critical natural resource. Their certification confirms that the products that bear it are manufactured using sustainable environmental practices. Cornerstone's ResinDek® engineered flooring panels can be constructed with materials that have received FSC® Certification upon request.

Cornerstone's FSC Certification is shared below.

LEED® CERTIFICATION

Established by the U.S. Green Building Council (USGBC), the Leadership in Energy and Environmental Design (LEED) green building rating system is the world's most widely used and recognized. Using Cornerstone's ResinDek® engineered flooring panels in construction can contribute to a variety of credits across both materials and resources and indoor environmental quality categories, as shown here.

Notes:

- All LEED credits/points are subject to interpretation/ruling by USGBC review team.

- More details about the LEED® Rating System can be found here.

WARRANTY, INSTALLATION INSTRUCTIONS & MAINTENANCE

INSTALLATION INSTRUCTIONS

CARE & Maintenance

WATCH THE FOLLOWING HOW-TO VIDEOS FOR RESINDEK FLOOR PANELS CARE AND MAINTENANCE

How To: Care and Maintain Your ResinDek® Mezzanine Flooring | Video Length: 0:53

How Do Autonomous Mobile Robots Work?

Autonomous mobile robots work using a laser light to bounce off the surrounding environment so that it can detect any obstacles in the robot's physical space. This allows the robot to have a map of the surrounding area and its work environment. Large obstacles are easy for the robot to avoid but cracks in a concrete floor may not be as easy to detect and could cause damage to your autonomous mobile robot and potentially delay productivity ResinDek warehouse decking panels help to reduce the risk of these potential hazards by providing a flat, level flooring surface with long lasting durability.

What Are The Different Types of Autonomous Mobile Robots?

AMRs are used for a variety of different tasks and applications. AMRs can be used for the following applications:

- AMRs that assist with the order picking process in a warehouse

- AMRs that transport inventory and products within a facility.

- AMRs that assist with sortation, such as high speed parcel sortation, Ecommerce order fulfillment and short-term sortation